The global recession in the last few decades has had a significant impact on the way industries operate. The recession has forced industries in the manufacturing sector to undergo a fourth industrial revolution, commonly referred to as Industry 4.0.

The transformation of the manufacturing industry is mainly dependent on Information Technology. Information Technology (IT) is driving the automation process. The task that has typically required several people to handle can easily be monitored and controlled from a computer screen and, in some cases, from mobile devices.

This industrial revolution is mainly in a bid to cut labor costs that keep on surging. The answer to the labor intricacy is solved by integrating automated systems and Information Technology (IT) solutions in manufacturing industries.

How has technology improved manufacturing process?

For many manufacturers, automation is the key to efficiency and eventual cost-cutting. Automation is not the only factor, but others like robotics also perform above expectations and at the lowest cost in the long run.

Automation encompasses three main components, i.e., machines, their computer-controlled programs, and the operators (humans). These three components are the basic foundation of the internet of things (IoT) that controls connected devices from a central point.

Automation in manufacturing has major significance inside the factory floor or the plant. Here, automation involves mechanizing process steps so that the required product is made with minimum involvement of humans.

Which Processes in Manufacturing Can Be Automated Using IT?

Processes that are commonly automated include welding, packaging, painting, and food preparation. These tasks require data collection, analysis, and interpretation, which are efficiently handled by the computer. Control systems collect and relay data to the computers from where processing takes place. For each problem in manufacturing, there is an IT solution.

Based on the end product and the steps to be followed, automation exists of several types and on various levels. The available or the needed machines and resources play a vital role in the type of automation to be implemented.

Let us look at common types of automation and their applications.

Types of Automation

Fixed Automation

This is where a simple application is utilized alongside pre-programmed instructions. Such an assembly is relatively fixed and cannot adjust to modifications in product design. To make the best out of this type of automation, the purpose must be a single one.

Where it is used

Pros & Cons of Fixed Automation

Pros:

Cons:

Programmable Automation

Just as the name suggests, programmable automation allows continuous changes in the product. For that reason, this automation is best practiced by manufacturers producing goods in lots or batches. The system constitutes a physical system and a program. Making something new requires a program written for that product. Manufacturers change programs only or variables, but the system remains the same.

This automation type is being rapidly adopted in developing countries and promises even a bigger global footprint.

Where it is used

Pros & Cons of Programmable Automation

Pros:

Cons:

Flexible Automation

Flexible automation is an advance version of the programmable automation. A manufacturing line using flexible automation can produce variety of products without wasting time when changing from one product to the other.

Flexible automation saves time that would otherwise require for reprogramming, and it can be scheduled so that different batches can be made without switching programs. This is the main difference between this automation type from the programmable type.

Where it is used

Pros & Cons of Flexible Automation

Pros:

Cons:

Totally Integrated Automation

There is another less popular automation technique known as Totally-Integrated Automation (TIA). It was introduced by Siemens Automation and Drives. The main feature of TIA is the use of a common software environment, communication method, and data management system.

This feature makes it applicable in many unique industries such as plastic processing and 3D printing, automotive, packaging, and manufacture of general, specialized, and other mechanical equipment. Food processing industries are also embracing this automation, proving the prowess of IT solutions for manufacturing.

Where it is used

Pros & Cons of Totally Integrated Automation (TIA)

Pros:

Cons:

How Information Technology Support in Manufacturing Industries

Information technology has improved manufacturing Industry significantly over the last two decades through advancement and innovation. As smart devices are becoming extremely common, equipment manufacturers are developing mobile applications that can monitor an entire plant.

This valuable information can be helpful in both, proactive and reactive actions for any problems in the plant, thus saving on the maintenance cost, time, and labor.

IT has accelerated the process of automation in the last decade more than ever in human history.

As with every innovation, with numerous benefits, these are some negative results of the 4th Industrial revolution in manufacturing industries.

Some of the most common drawbacks in general are:

With automation, comes other needs that only IT solutions for manufacturing can handle. The most common applications are:

Artificial Intelligence

Artificial intelligence, as a part of machine language, can be used to optimize production and transactions. This is what smart manufacturing entails. All the manual systems are overhauled and replaced with an AI system. AI collects data from all networked components in a connected factory. The data is used to reprogram workflows and optimize machinery. AI also uses the collected information to determine the optimum parameters that can be adopted to maximize revenue.

Cloud Computing

Data collected and information produced is so enormous that it may cost a company considerable money on setting up and continually upgrading local storage. Manufacturers who find this cost unnecessary can opt for cloud computing. With cloud data storage and access, all points in a connected factory can access any required information instantly and easily as it is accessed from local storage.

Ease in Data Analytics

For cloud computing and AI to fully monitor manufacturing processes, a vast amount of data is collected, and more information is generated. This data analysis would take a lot of time to make valuable decisions and derive conclusions.

The IT solution for this manufacturing challenge is Big Data analytics that processes data swiftly. Such systems can be connected to AI to facilitate faster decision-making and prompt response. In the end, the manufacturer saves a lot of money that could have otherwise used to pay for data storage and analysis.

Industrial Internet of Things (IIoT)

IIoT connects data, people, and machines in the manufacturing industries. These connections are not limited to time or distance. The connection of people and machines to the internet allows real-time data availability.

IIoT is very reliable as every component can be connected to the internet. The best production efficiency can be achieved by monitoring and analyzing real-time data throughout the manufacturing operation.

Cybersecurity

As online presence keeps on growing, the importance of cybersecurity has also increased. More and more devices are being connected to the internet, some of which are pathways to attackers. The IIoT, remote access, and stored data on the cloud are prime targets for hackers.

These vulnerabilities in manufacturing industry are needed to be addressed and closed by employing efficient IT Cybersecurity tools. Cybersecurity focuses on detecting hacking or data breaches, protecting against viruses, and responding to attempt of attacks that were already made.

Simulation

For successful implementation of smart manufacturing, computer simulations are made to represent the dynamics of a business system. In the simulation, the model is tested against real-world scenarios. The results can help in making the final adjustments to the product before manufacturing and diagnose any unknown problems beforehand.

Other things, such as the speeds of various drives, the rate of discharge, and the estimated time to complete, can be tested easily on simulations. This is another area where IT solutions are beneficial for manufacturing industries.

Benefits of digital transformation in manufacturing Industry

Digital transformation is like a constant gradual evolution in manufacturing industries. It is a process of transforming from traditional labor-intensive manufacturing methods to modern automated systems that save on time, labor and achieve results otherwise impossible. The IoT is among the most critical forms of digital transformation apart from automation.

Internet of Things (IoT) in the Manufacturing industry

On its own, the Internet of Things could not see such widespread adoption if it's not for the special industrial benefits associated with it. Most of these benefits are long-term, but there are some immediate wins as well.

Here are four major areas in manufacturing industry that have seen successful application and adoption of the technology:

1. Monitoring Machinery Usage

According to an ITIF study, the use of IoT applications can increase productivity by 10% to 25%. Monitoring machine resource utilization by IoT can boost the global economy by $1.8 trillion, says the study.

IoT uses sensors to collect data from every device. This data is transmitted to the cloud storage for processing and analysis. After the key performance indicators have been identified, they are relayed back to the factory system via the web or mobile-based platforms. This help workers to interpret and adjust production accordingly.

2. Product Quality Control

There are two basic ways in which the quality of production can be supervised. The most common is the inspection of work in progress (WIP) throughout the production sequence. The other is by monitoring the calibration status of the machines that make the product.

Machine operational parameters such as the speed of Variable Speed Drives (VSDs), humidity, temperature, and vibration can be monitored in real-time. In case of any breach in the threshold, an alert is sent to the command center.

In IoT, smart tech suggests corrective measures, and in some cases, the system may have permission to take corrective actions.

3. Monitoring Workplace Safety

Safety is vital to critical industries like gas, mining, transport, and oil and places with persons stationed along production lines.

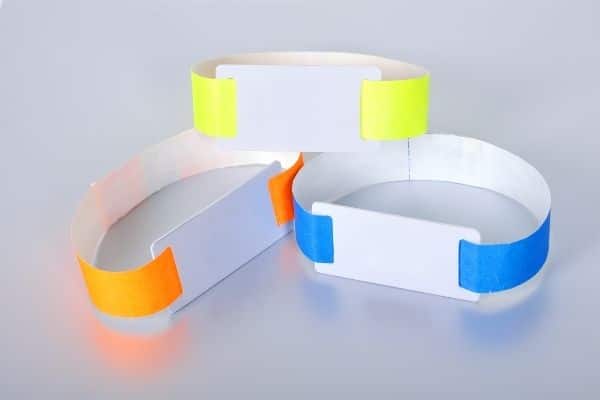

The most common application of IT solutions for manufacturing in such industries is RFID tags and wearable gadgets with sensors. RFID tag relays the location of a worker while wearable sensors collect data such as pulse rate, temperature, and galvanic skin response of a worker.

The data is transmitted to the cloud computing center and compared against dependent parameters such as environmental weather conditions and existent work plan systems.

If an unusual heart rate is detected in a worker, it is immediately alert to them and to the manufacturing supervisors who can relieve the worker. This helps avert would-be overexertion and any resultant consequences.

4. Industrial Onsite Assets Management and Allocation

IoT offers smart management of resources in a manufacturing setup, along with other applications. The asset-related functions that can be optimized through IoT include; proper asset allocation, prolonged machine service life, reliability, and revenue on capital.

IoT manages industrial assets in three areas, namely; industrial asset tracking, inventory management, and predictive maintenance.

To use IoT for industrial asset tracking, the asset to be tracked is tagged with an RFID card that has information on the location of the equipment. If the equipment, say a mobile batching unit, is deployed, a sensor at the yard entrance scans the serial number of the equipment. The serial number could be linked with the operator assigned to the machine.

IoT is applied in inventory management to automate tracking and coverage. This ensures real-time status and location of equipment or a connected item is known; thus, the short acquisition time can be achieved.

Predictive maintenance helps a manufacturing setup to avert costs on corrective maintenance. According to Deloitte, the use of IoT is expected to reduce the overall maintenance cost by up to 40%. IoT monitors the status and calibrations of inline equipment and parts. Information on the various parameters is cloud processed based on the equipment model, setup mode, and other relevant parameters. More data from the ERP is compared against the input and relayed back to the onsite workers or operators.

IT Solutions Facilitating the Adoption of IoT

Cost reduction

Optimized manufacturing costs mean maximum revenue can be generated at the lowest possible cost. Things that contribute to reduced costs are;

Shortened Time To Market (TTM)

Smart manufacturing through IoT means the shortest production times can be achieved. If IoT is properly integrated with AI, mind-blowing results are achievable. An example is the adoption of IoT by Harley-Davidson to reduce manufacturing time considerably from 21 days to 6 hours. This was done in the company's New York factory.

Mass Customization

Production of a new product begins with a single variant. As the trade diversifies, more variants, i.e., SKUs, are necessary. With IoT, manufacturing operations and batch sizes can be monitored and data stored within no time. Previously, the process used to be tedious and impossible in some cases.

Need for Synchronized Monitoring

A manufacturing industry that has automated processes requires less staff to man the plant. To be able to monitor the various processes that depend on each other, IoT becomes a necessity. IoT facilitates corrective actions to be done not only at one point but also on other areas that may have been affected by a breakdown or change.

Some Challenges on the Way

IoT adoption has, however, not been without challenges. Some of these problems encountered by manufacturing industries include:

Final Word

IT solutions for manufacturing have played a pivotal role in the transformation of industry 4.0. Overall, the IoT application has reduced the costs of operation and maximized resource allocation and utilization. On the other hand, automation has reduced production timelines and improved accuracy in manufacture. Adopting IT solutions for manufacturing challenges may be a daunting task if done from scratch. The cost is also high, but since the future of modernization in manufacturing depends on these solutions, the earlier a manufacturer embraces the technology, the sooner the initial costs break even.

Sources:

https://www.sciencedirect.com

https://www.emerald.com

https://global.hitachi-solutions.com

https://www.hashmicro.com

https://www.businessnewsdaily.com

https://www.encompass-inc.com

https://www.scnsoft.com

https://www.i-scoop.eu

https://www.manufacturingglobal.com